ဟွေဒရောလိတ်ဖလူးက ကိရိယာများတွင် အသုံးပြုသော အရွက်အရေမျိုးတစ်ခုဖြစ်ပြီး၊ ကိရိယာ၏ များစွာသော အစိတ်အပိုင်းများအကြား အင်အားကို ရောင်းဝယ်ပေးရန်အတွက် အသုံးပြုသည်။ omm 32 hydraulic motor ဒါက လမ်းဆိုင်ရာ လိမ္မန်လိုပဲ။ လမ်းဆိုင်ရာ လိမ္မန်က ကားများအား ရပ်နိုင်၊ သွားနိုင် ပြောပြပါတယ်။ ဒီဝါလ်က ဟွေဒရောလိတ်ဖလူးအား ဘယ်လမ်းကို သွားနိုင်သလဲဆိုတာကို ပြပေးပါတယ်။ ဒါကြောင့် ကိရိယာကို ဘယ်လိုလုပ်ရမလဲဆိုတာကို သင်ပေးပါတယ်။

ဟိုင်ဒရောလစ်နှင့်ပတ်သက်သောအဓိကဆိုင်ရာအသုံးပြုမှုများထဲမှတစ်ခုမှာ အများစုသောကူးယူမှုများ၊ အထူးသဖြင့် လျှော့ချမှုနှင့်သတ်မှတ်မှုအရည်အချင်းစွာရှိသောလုပ်ဆောင်မှုများအတွက် အချိုးအစားရေးသားထားသော ဒါရဗာလုံးများဖြစ်သည်။ ဒီဒါရဗာလုံးများသည် လှုပ်ရှားမှုကိုသာ မကိုင်တွယ်သောသူမဟုတ်ဘဲ၊ ကူးယူမှု၏အမြန်နှင့်လည်းကြောင်းကိုကိုင်တွယ်သည်။ ကိုင်တွယ်ရေး၏လိုအပ်ချက်သည် ကူးယူမှုများအား မျိုးမျိုးသောလုပ်ဆောင်ချက်များကို သတ်မှတ်မှုစွာလုပ်ဆောင်နိုင်စေရန်အတွက် အရေးကြီးသည်။

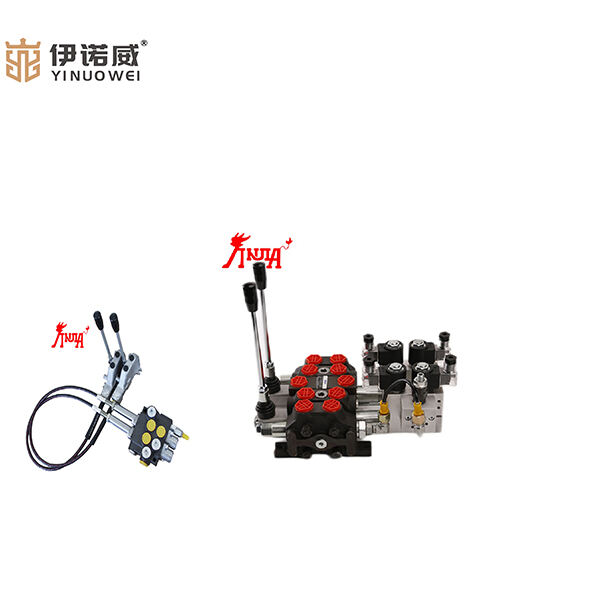

အဲဒီလို ကောင်းမွန်သော ရုပ်ပိုင်းကိရိယာများဟာ ဟိုက်ဒရှိုလိတ် ဒါရှင်းချိုးဖြတ် ကိရိယာများ မရှိခဲ့ရင် လုပ်ဆောင်ခြင်းက အခြေခံဖြစ်နိုင်မည်။ သူတို့ဟာ ထိုလောက် ပြင်းထန်သော လုပ်ဆောင်မှု၊ တိကျမှုနှင့် ကျွမ်းကျင်မှုဖြင့် လုပ်ဆောင်နိုင်မည်မဟုတ်ဘဲ။ မှန်တဲ့ အဆောက်အအုံမရှိတဲ့အခါ အရာတစ်ခုကို တည်ဆောက်နေတယ်ဆိုရင် အခက်အခဲရှိနိုင်တယ်လို့ မျှဝေပြီးပါတယ်! ဒါရှင်းချိုးဖြတ် ကိရိယာတွေဟာ ကောင်းမွန်သော ရုပ်ပိုင်းကိရိယာတွေအတွက် လိုအပ်သော လုပ်ဆောင်မှုကို ပေးပို့ပါတယ်။ ထို့ပြင် ပণ္နိုင်ရာများကို ထုတ်လုပ်ခြင်း သို့မဟုတ် တိကျမှုမြင့်တဲ့ လုပ်ဆောင်ချက်တွေကို ပြုလုပ်ခြင်းအတွက် အထင်ရှားပြီးဖြစ်ပါတယ်။

ထို့ပြင် ဒီ ကိရိယာတွေဟာ လက်မှတ်များတွင် အထူးသဖြင့် အလုပ်အကိုင်များတွင် အမြတ်အထွေထွေတွေရှိပါတယ်။ ဟိုက်ဒရှိုလိတ် ဒါရှင်းချိုးဖြတ် ကိရိယာတွေရဲ့ အဓိကဆုံး အမြတ်အထွေထွေတစ်ခုဟာ ဟိုက်ဒရှိုလိတ် ရောင်းဝယ်စွာ လွှမ်းမိုးမှုကို ချိုးဖြတ်ခြင်းဖြစ်ပါတယ်။ ဒီလို တိကျသော အခြေအနေက ကောင်းမွန်သော လုပ်ဆောင်မှုကို ရုပ်ပိုင်းကိရိယာတွေအား ပေးပို့ပါတယ်။

ဒီဗို့ရှင်တွေရဲ့ အဓိက အကျိုးကျေးဇူးက ၎င်းတို့ဟာ ဖိအားမြင့်နဲ့ အပူချိန်မြင့် အခြေအနေတွေကိုလည်း ခံနိုင်စွမ်းရှိတာပါ။ အဲဒါကြောင့်မို့လို့ စက်ရုံများတွင် ဒါမှမဟုတ် စက်ပစ္စည်းများအား များစွာ အသုံးပြုရန် လိုအပ်တဲ့ နေရာများတွင် သုံးရန် သိပ်ကို အဆင်ပြေပါတယ်။ အပူချိန်ဟာ အလွန်မြင့်လာတဲ့အခါ (သို့) ဖိအားက အရမ်းကြီးတဲ့အခါမှာ ၎င်းတို့ဟာ ပုံမှန်အတိုင်း ဆက်လက် လုပ်ဆောင်ပါတယ်။

စက်ပစ္စည်းအစိတ်အပိုင်းတိုင်းလိုပဲ လျှော့အား ဟိုက်ဒရိုလစ်လမ်းညွှန်ထိန်းချုပ်ရေး ဗို့အားတွေဟာ ပုံမှန်ပြုပြင်မှု လိုအပ်ပြီး တစ်ခါတစ်လေမှာ မှန်ကန်တဲ့ လုပ်ဆောင်မှုကို အာမခံဖို့ ပြင်ဆင်မှု လိုအပ်ပါတယ်။ ကစားစရာတွေ (သို့) ကိရိယာတွေလိုမျိုး ထိန်းသိမ်းဖို့လိုသလို ဒီဗို့အားတွေလည်း လိုပါတယ်။ ဗို့အားကို ပုံမှန် ပြုပြင်ပေးခြင်းက ပျက်စီးမှုကို ကာကွယ်ပေးပြီး ထိရောက်စွာ လည်ပတ်စေပါတယ်။

ပြဿနာတစ်ခုဖြစ်လာသည့်အခါ ဒါကို ပြီးခဲ့သော ဆောင်ရွက်မှုလိုအပ်နိုင်သည်။ ဆောင်ရွက်မှုတွင် ပျောက်ဆုံးမှုမရှိ၊ ဝါလ်က သန့်ရှင်းလျှင်၊ ဝါလ်က အလုပ်လုပ်နိုင်ပါသလားဆိုတာ စမ်းသပ်ခြင်းပါဝင်သည်။ ယင်းဝါလ်များကို ထိန်းသိမ်းခြင်းက ကိရိယာများအား မှန်ကန်စွာ လုပ်ဆောင်နိုင်စေရန် အရေးကြီးပါသည်။